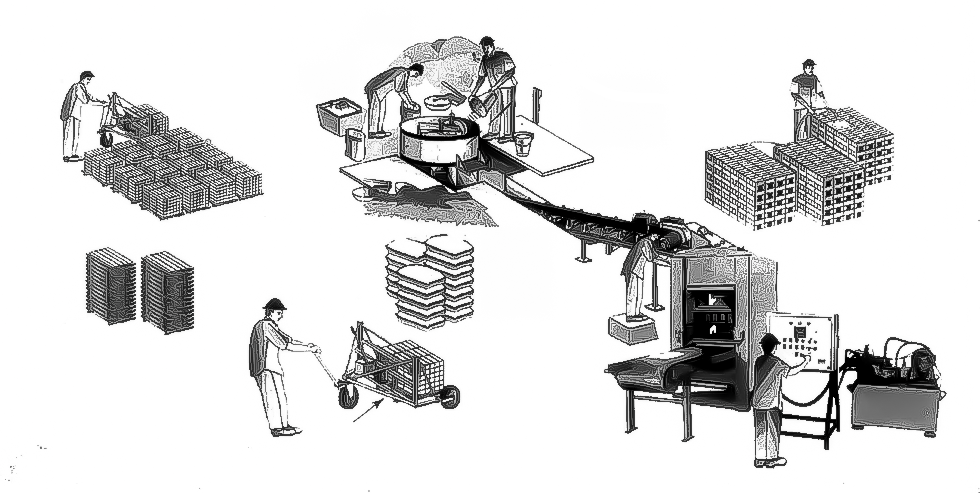

We, popularly known as SVT Groups are well established in in diversified business sectors such as Real estate, Blue Metals, Transport, etc. in Salem & Hosur for the past 15 Years & has now spread our wings into a New Venture of Manufacturing & Selling Fly ash Bricks & Solid Blocks in Coimbatore & Chennai.

Our Supply is not just confined to Tamil Nadu but also extends to Private Sectors, Slum Clearance Board & PWD even in our neighboring states – Kerala, Karnataka, Andhra Pradesh & Telangana.

Our Major Concept is to “Save Cost in Energy & Construction.”

“To be in the forefront of creating awareness about environment & to be the largest player in the field of fly-ash brick production”.

“To provide and promote an eco-friendly technology and strenthen the brick manufacturing sector for the ultimate benefit of its customers and soceity”.

Speciality: The use of cement will increase the bonding and strength of the bricks.

| Properties | Clay Bricks | Flyash Bricks | Remarks |

|---|---|---|---|

| Density | 1600-1750 kg/m3 | 1700-1850 kg/m3 | Higher Loading Bearing |

| Compressive Strength | 30-35 kg/cm2 | 90-120 kg/cm2 | Higher Loading Bearing |

| Absorption | 15-25 % | 10-14 % | Less Dampness |

| Dimensional stability | Very Low Tolerance | High Tolerance | Saving in Mortar up to 25% |

| Wastage During Transit | Up to 10% | Less than 2% | Saving in Cost up to 8% |

| Plastering | Thickness varies on both sides of the wall | Even on both sides | Saving in plaster up to 15% |

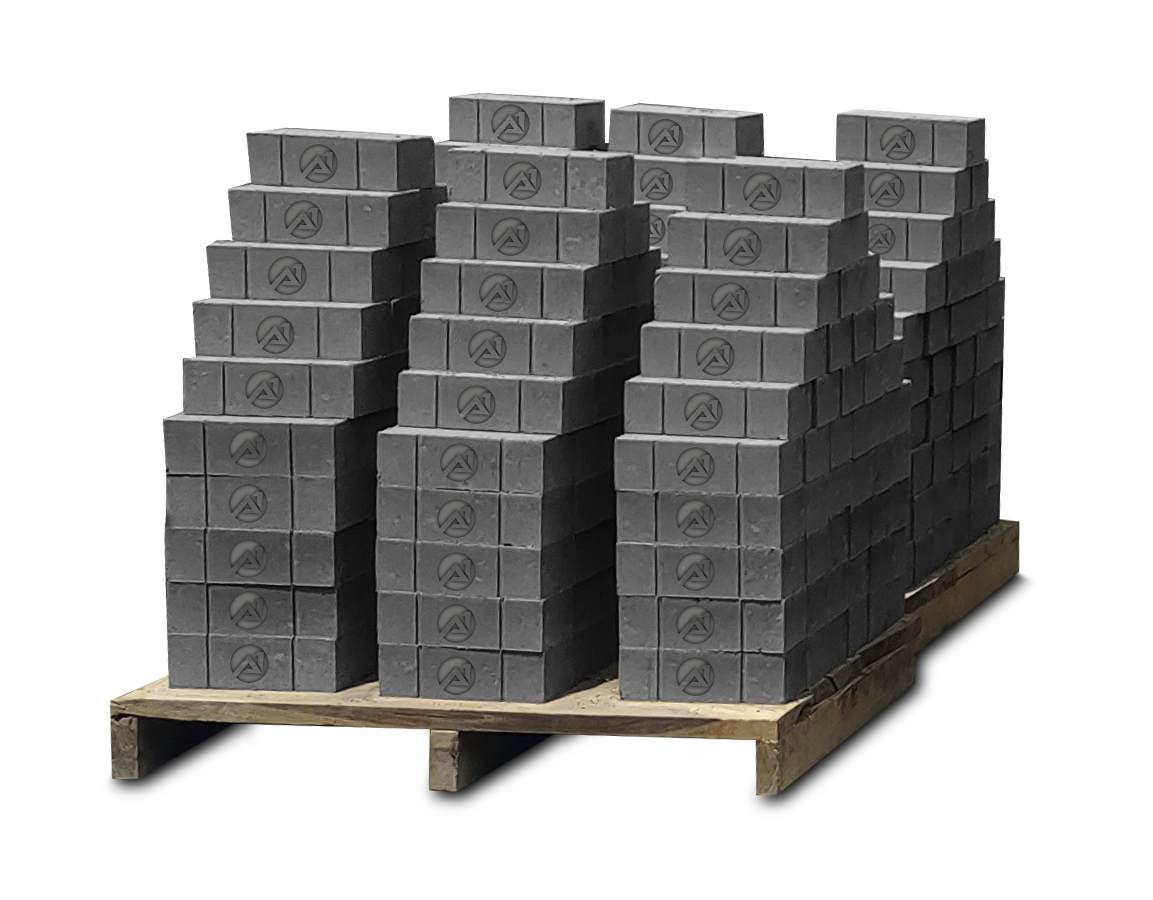

A1 Bricks

Hi there!

How can I help you?